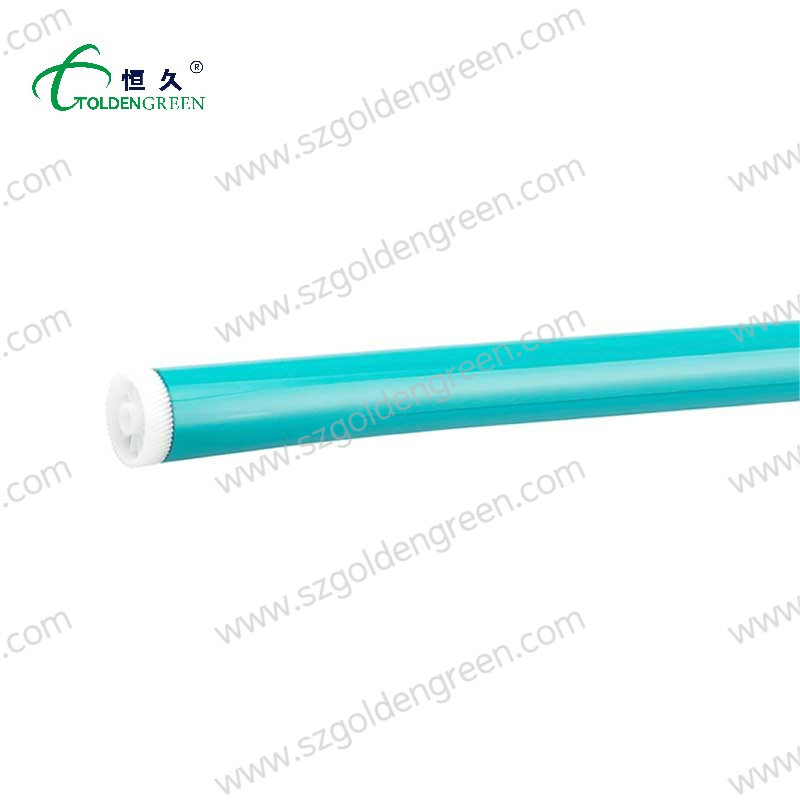

OPC drum refers to the Organic Photoconductor Drum, which is a core component in laser printers, photocopiers, and multifunction printers. It is a photoelectric conversion device formed by coating an OPC material on the surface of a conductive aluminum cylinder. Here is a detailed introduction:

Working Principle

The OPC drum is an insulator in the dark and can maintain a certain electrostatic charge. When irradiated by light of a certain wavelength, it becomes a conductor and releases charge through the aluminum base to form an electrostatic latent image.

Role in the Printing Process

In the printing process, the OPC drum first needs to be uniformly charged with static electricity. Then, a laser beam or LED light source scans across the surface of the drum to discharge specific areas, creating an electrostatic image of the content to be printed. Next, toner particles are attracted to the charged areas on the drum to form the image or text. Finally, the image is transferred from the drum onto paper through a combination of heat and pressure.

Advantages

The OPC drum has the advantages of a wide range of material sources, low price, excellent performance, and no pollution. It has replaced other photoconductive materials and become the mainstream in the market.

Post time: Apr-24-2025